Preserve Your Look. Joint Sealing Done Right.

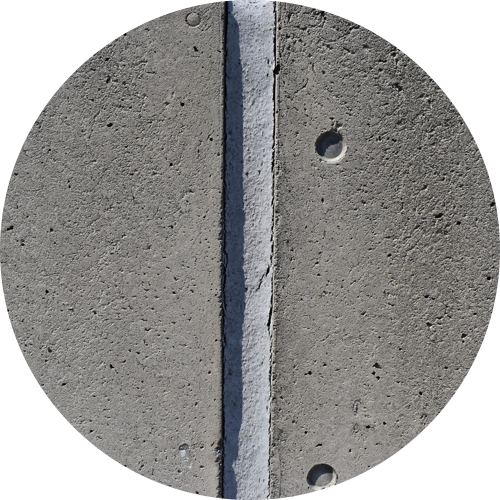

Concrete joint filling is the process of filling the saw cuts in concrete surfaces with a material that can withstand the expansion and contraction of the concrete. The joints in concrete structures are important because they allow for movement and relieve stress, but if left unfilled, they can weaken the structure over time and lead to cracking. Concrete joint sealing also prevents water, dust, dirt, and other debris from collecting in the joint, which can cause further damage.

Filling concrete joints is routine work for Commercial Flooring Columbus. Our team of experts will quickly fill and seal your concrete floor joints with high-quality materials. We take pride in our work and have been trained by some of the best concrete artisans in the industry. When we’re finished, your facilities will have safe and aesthetic concrete floors that are resistant to water, dirt, dust, and other debris. Contact us today to discuss your next concrete flooring project and get a free estimate.

Frequently Asked Questions

What is concrete joint sealing and why is it important?

Which types of joints need sealing?

What types of sealants are used for concrete joints?

Can joint sealing be done on older concrete?

Request a Free Estimate

The Benefits of Joint Filling & Concrete Sealing

Improved Safety & Cleanliness

Joint filler helps to level the surface of your concrete floors, reducing tripping hazards. Joint filler also reduces the amount of dirt, dust, and fungi that can get into the joint, making your floors more hygienic and easier to clean.

Improved Durability

Filling your joints protects them from damage and keeps water, dirt, and other debris from collecting in these crevices. This extends your floor’s lifespan by reducing cracking and other forms of damage over time.

Waterproofing

Concrete joint filler fills in the gaps in concrete foundations to prevent water from seeping in. Water can cause a variety of problems in concrete floors, including cracking, spalling, and the growth of mold and mildew. Filling and sealing your concrete joints reduces the risk of water damage.

The Joint Filling Process

Whether you want a space that’s sleek and modern, rustic and charming or something in between, epoxy coatings can help you achieve that look. There are thousands of design and color combinations possible, making epoxy a customizable and versatile flooring solution for your residential, commercial or industrial property. From colorful epoxy flakes to elegant metallic marble to understated knockdown texture and more, epoxy coatings give you visually appealing floors that are built to last.

At Commercial Flooring Columbus, our experts are ready to create your ideal floor. During our process, we’ll discuss your flooring needs, talk through the different coating options available, then get to work and install the decorative epoxy coating for results you can see.

Clean

First, we brush and vacuum your floor’s seams to remove any dust or debris left over from the saw cutting process.

Fill

After the grooves have been cleaned, we apply the joint filler. We can use a variety of materials, including silicone, polyurethane, epoxy, or polysulfide, depending on your project’s needs.

Level

Next, we level the joint filler to ensure it’s even. Leveling the joints reduces the likelihood of cracking in the future.

Cure

Once the joints have been leveled, it’s important to let the filler material dry completely. This can take anywhere from a few hours to several days, depending on the material.

Seal

Finally, once the filler has cured, we seal the surface to further protect your concrete floor from dirt, dust, and other contaminants. Sealing your concrete floor also makes it waterproof.

The Hazards of Unfilled Concrete Joints

Tripping

Unfilled saw cuts can create tripping hazards, especially in high-traffic areas. This can result in serious injuries, including broken bones and head injuries.

Dust

Unfilled saw cuts can release dust into the air, posing a respiratory hazard, especially for people with allergies or respiratory conditions like asthma.

Moisture

Unfilled saw cuts can also allow moisture to seep into your concrete surface, which can lead to mold and mildew growth. This can lead to indoor air quality issues, including odors and respiratory irritation.

Concrete Deterioration

Unfilled saw cuts can weaken your concrete floors and make them more vulnerable to further damage. It’s best to fill your concrete joints to avoid the need for expensive repairs in the future.

Concrete Joint Filling Applications

Many facilities require concrete floor joints to be filled. We provide joint filling services for the following applications in Columbus and central Ohio.

Industrial Facility Floors

Your factory, warehouse, or other industrial facility requires low-maintenance concrete flooring that can withstand heavy machinery and foot traffic. Filling your concrete joints helps to prevent the formation of cracks, which is critical in these high-traffic environments.

Retail Facility Floors

Malls, grocery stores, and other shopping centers need to have smooth and durable concrete floors. Concrete joint filling improves the appearance of your store’s floors and makes them easier to clean. Keep your customers happy with well-maintained concrete floor joints.

Food Grade Facility Floors

Food grade buildings such as restaurants and food processing facilities require a hygienic flooring surface. Joint filling helps prevent bacteria and other contaminants from collecting in the cracks of your concrete floors, making the floor more sanitary and easier to clean.

Healthcare Facility Floors

Hospitals, clinics, and other healthcare facilities also require sanitary flooring. Filling concrete joints in these facilities helps to prevent the formation of cracks, which can harbor bacteria and other contaminants. Joint filling makes your concrete floors easier to clean and maintain, which is important in these environments where hygiene is a top priority.

Educational Facility Floors

Schools, universities, and other educational facilities experience a lot of foot traffic and require durable and low-maintenance flooring solutions. Filling concrete joints in these settings helps to prevent the formation of cracks and makes your floors easier to clean.